Teknomek manufacture a wide variety of furniture and equipment using stainless steel. In this guide we discuss it in detail, what it is, the different grades and what their main features and benefits are.

What is steel?

Steel is an alloy of iron and carbon. Steel has improved strength and fracture resistance compared to other forms of iron. Since the primary element used in the alloying process, other than iron itself, is carbon, steel is defined by its carbon content. Steel can have anywhere between 0.002% and 2.1% carbon by weight, but always contains smaller amounts of the element’s manganese, phosphorus, sulphur, silicon, and traces of oxygen, nitrogen and aluminium in addition to carbon and iron.

While these elements are required for an alloy to be accurately referred to as 'steel', others such as manganese, nickel, chromium, molybdenum, boron, titanium, vanadium and niobium can be added to modify the characteristics of the alloy.

What is stainless steel?

Stainless steel is a metal alloy, predominantly iron, containing a minimum of 10.5% chromium. The chromium reacts with oxygen in the air to form a thin layer of chromium oxide on the surface of the metal. This protective "passive” layer protects the steel from rust and corrosion.

How does stainless steel differ from regular steel?

Under conditions of high moisture and high salinity, the iron found in steel will oxidise to form iron oxide. A layer of iron oxide on the surface of the steel can increase the rate of its own formation, thus encouraging more corrosion to occur, and causing the structure of the steel to be compromised.

Whereas stainless steel contains a sufficient proportion of chromium to facilitate the formation of a layer of chromium oxide on the surface of the metal. This layer of chromium oxide does not catalyse the formation of more chromium oxide and acts to protect the iron within the structure from oxidation, a process referred to as 'passivation'. This makes the stainless steel incredibly corrosion resistant.

Grades of stainless steel

There are two main labels around stainless steel alloys: being 'families' and 'grades'. The family refers to specific properties and give an idea as to the ratio of various metals in the alloy. Grades are used as a classification system to facilitate easy identification of the compounds used. Stainless steel falls into four distinct families. The table below shows each family with relevant details to note.

| Family | Corrosion resistance | Strength / hardening | Magnetic |

|---|---|---|---|

| Austenitic | Excellent | High strength / can’t be hardened | No |

| Ferritic | Moderate | Can't be hardened very much | Yes |

| Duplex (mix of austenitic and ferritic) | Good | High stength | Weak, depends on the composition |

| Martensitic | Good, but lower than austenitic | Strong and hard | Yes |

Since steel can be alloyed with an infinite number of combinations of alloying elements, a classification system has been developed to facilitate easy identification of the compounds used. Stainless steel has its own list of classifications, each are explained below with application examples and why they are suitable.

| Stainless steel grade | Family | Descriptive | Examples of application | Suitability reasoning |

|---|---|---|---|---|

| 200 series | Austenitic | Chromium-nickel-manganese alloy | Indoor applications such as appliances / white goods interior automotive components. | Where high corrosion resistance isn’t required. |

| 300 series | Austenitic | Chromium-nickel alloy | Food processing equipment, chemical processing equipment, medical devices, construction materials, household appliances including sinks. | Due to its chromium content (c.18-20%) and nickel (c.8-20%) for excellent corrosion resistance, making it suitable to use harsh cleaning chemicals. It also has excellent formability and strength. |

| 400 series | Ferritic and Martensitic | Chromium alloy | Car exhausts, some higher-grade cutlery steel, replica swords and knives. | One of the cheapest stainless steel available. |

| 500 series | Martensitic | Heat-resistant chromium alloy | High temperature environments (furnaces, heat exchangers), industrial applications (boiler parts, turbine blades) and automotive (exhaust components, heat shields). | Due to its high heat resistance. |

| 600 series | Martensitic | Alloy formed by precipitation hardening (a special heat treatment process) | Aerospace, chemical processing equipment, oil and gas, nuclear reactors, medical devices (implants). | Due to its high heat resistance. |

| Type 2205 | Duplex (mix of austenitic and ferritic | Mixed alloy | Oil and gas exploration (pipelines, wellheads), chemical processing equipment, marine environments, paper and pulp industry. | It is a premium, high cost choice for demanding applications where high strength, exceptional corrosion resistance and good weldability are all crucial factors. |

| Type 2304 | Duplex (mix of austenitic and ferritic | It is a "lean duplex" grade; It primarily relies on chromium (c.23%) and nickel (c.4%) as it has little or no molybdenum content. | Chemical processing equipment, paper and pulp industry, food industry; suitable for certain food processing equipment or tanks, water treatment; piping and equipment handling treated water, construction. | It offers a more economical price point compared to some other duplex grades. It is a good balance between affordability, high strength and good corrosion resistance. However, not ideal for environments where there are extreme temperatures or where aggressive chemicals are used. |

The 300 series of stainless steel is one of the most popular and versatile families of stainless steel. There are many grades within the 300 series, we have highlighted the most popular and explained their differences here:

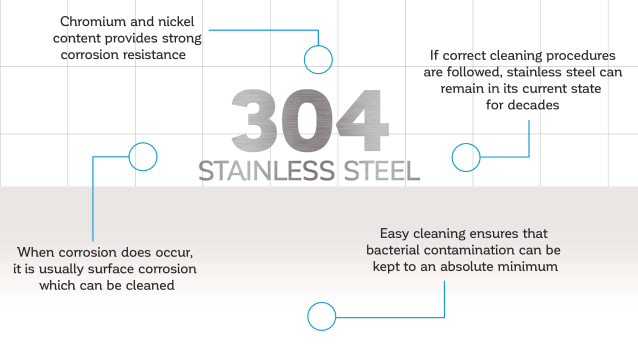

304-grade stainless steel

The most common type of stainless steel. This grade has an 18-20% chromium content and an 8-10.5% nickel content by mass. This grade offers impressive strength, as well as incredible corrosion resistance, lending it to applications in which contact with food, chemicals or fresh water must be tolerated. 304-grade stainless steel also has properties which make it well-suited to welding and machining applications, thereby making it an excellent material for use in making machined parts.

316-grade stainless steel

The second most common grade of stainless steel is 316. The physical and mechanical properties are very similar to 304-grade, but the key difference is that 316-grade stainless steel incorporates about 2-3% molybdenum. Molybdenum gives the steel a stronger corrosion resistance and has the ability to protect against chlorides and other harsh environments such as in food manufacturing with high salt contents. 316-grade stainless steel is also used in Teknomek’s Hygienox range of cleanroom-focused furniture & equipment. Our standard range of hygienic products are made in 304-grade stainless steel, but they can also be manufactured in 316 if required. Please contact us below for further information.

What is 304L and 316L grade stainless steel

These are low carbon versions of stainless steel, which reduce the risk of carbide precipitation during welding, resulting in improved weld strength and quality. This is particularly beneficial when manufacturing hygienic furniture for the food and pharmaceutical sectors.

Electropolished finish on stainless steel

This is a process that removes a microscopic layer from the surface of the stainless steel to provide a smoother finish, removing surface contaminants and biofilms that can harbour bacteria. It can also make the cleaning and disinfection process easier and quicker, thereby also lowering running costs.

Further information on 304/304L, 316/316L and electropolishing can be found in our article about the benefits of stainless steel.

Need advice about the different grades of stainless steel and other hygienic materials?

Contact our Teknomek experts today.